Computational Modelling for Combustion Technologies and Hazards

Combustion

Combustion science underpins applications which have revolutionized industry and society in general over the past century.Since the end of the Second World War there has been an enormous expansion in academic combustion research.The unfortunate fact is that such research has concentrated its activities in the area of 'easily-soluble' combustion problems or in the development of technique for the sake of technique.The gap between academic combustion research and practical applications in combustion systems has, if anything, widened over the last forty years.To take an example, there has been little research in recent decades which has thrown light on, or is even remotely applicable to, the kind of relatively small high temperature flames used in metal processing.Rule of thumb is still the order of the day in burner system design.One can make the same statement for other areas: Otto and Diesel cycle engines, gas turbine combustion chambers, large turbulent flames for process plant, pulverized fuel/oil flames for steam-raising etc.

The modern way to bridge the application gap is to rely on computational modelling and several relatively expensive computational fluid dynamics codes are available commercially which claim to solve combustion simulation problems for complex flames.One needs to be careful in evaluating such claims since the 'black box' cores of such programs may contain crude and inaccessible combustion models which may limit the usefulness of the package in particular areas.

Seicomb has considerable experience with combustion modelling and provides expertise which can be applied directly to combustion problems or used to evaluate the efficacy of CFD approaches to individual combustion applications.

Recent projects undertaken by Seicomb have included the following:

- Detailed reaction modelling for laminar flames with the aim of predicting levels of environmentally-harmful emissions

- Modelling of the turbulent combustion of natural gas in a combustion chamber of specific design

- Prediction of flame temperatures for combined gas-solid combustion

- The modelling of compression-ignition cycles based on catalytic combustion to extend the Diesel fuel range to light fuels

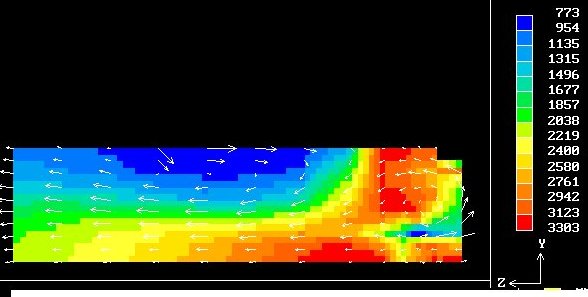

The above figure shows the temperature half-field for a natural gas-oxygen co-axial diffusion flame modeled by computational fluid dynamics code. The temperatures range from 773 K (blue) to 3303 K (red).

Hazard analysis

Many process hazards involve explosions caused by plant component failure and adventitious sources of ignition.Again, there are commercial CFD codes available which aim to predict the consequences of particular chains of plant incident and, once more, there is often doubt about the general applicability of such models to different plant circumstances.Seicomb provides critical expertise to evaluate the significance of such questions.

Recent projects undertaken by Seicomb include:

- The prediction of explosion development in closed volume environments for individual fuel types

- The prediction of the likelihood of the occurrence of a highly-destructive detonation in a certain design of process plant following adventitious ignition of specific gaseous fuel-oxidant mixtures